Perfumers: The Art and Science Behind Every Scent

How creativity, chemistry, and compliance shape modern fragrances

Introduction

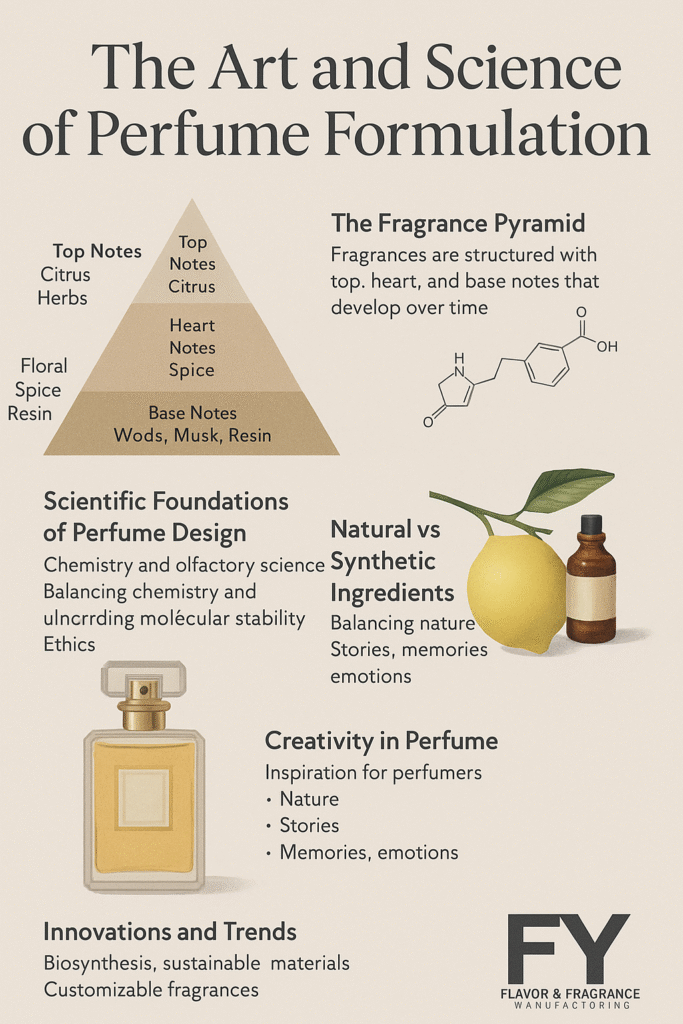

A perfumer—often called a nose—designs fragrances that are emotionally resonant, technically robust, and legally compliant. Beyond poetic accords and brand storytelling, modern perfumers operate at the intersection of sensory art, analytical chemistry, and regulatory science. They balance natural extracts and synthetic aroma molecules; they design top–heart–base architectures that survive heat, pH, surfactants, oxidation, packaging, and global safety rules.

FY collaborates closely with perfumers across fine fragrance, body care, home care, and fabric care. With IFRA-compliant bases, GC-MS analysis, microencapsulation/immobilization, and ISO/Halal certifications, FY helps turn briefs into scalable, consistent, and market-ready scents—fast.

What Does a Perfumer Do?

- Translate the brief: Decode the brand story, target consumer, channel, price point, and constraints (e.g., IFRA category, allergens, cost-in-use).

- Build accords: Compose top, heart, and base notes using naturals and synthetics; iterate to reach signature, sillage, and longevity targets.

- Engineer for the base: Ensure the fragrance performs in real matrices—alcohol, oil, surfactant systems, polymers, fabric deposition.

- Validate and document: Sensory panels, GC-MS fingerprints, stability/compatibility tests, and compliance paperwork.

- Scale and sustain: Handover to production, monitor batch consistency, optimize cost and supply chain resilience.

The Perfumer’s Core Skill Set

- Olfactory memory & evaluation: Thousands of raw materials indexed by note, intensity, volatility, and synergy.

- Chemistry literacy: Functional groups, reactivity, volatility, oxidation, isomerism, and interactions with solvents and carriers.

- Regulatory fluency: IFRA categories, regional rules (EU/US/China), allergen labeling, and use-level ceilings.

- Formulation technique: Solvents (ethanol, DPG, IPM), fixatives (macrocyclic musks, ambroxide, resins), carriers, and delivery tech (microcapsules, immobilization).

- Analytical tools: GC-MS for fingerprints and troubleshooting; stability protocols for heat, light, oxygen, and pH.

- Collaboration: Work with evaluators, R&D, QA/RA, marketing, and operations for rapid, controlled iteration.

From Brief to Bottle: The Modern Perfumery Process

- Brief intake: Market, target persona, competitive set, references, performance metrics, regulatory category, BOM/cost targets.

- Palette strategy: Choose naturals (essential oils, absolutes, resins) and synthetics (single molecules, captive bases) aligned with goals.

- First mods (modifications): 3–6 early trials that test dominant ideas and anchors (citrus lift, floral heart, woody/amber base).

- Sensory screening: Internal panel narrows down 1–2 promising directions; check diffusion, balance, and off-notes.

- Base-side tests: Evaluate the fragrance in the real product base (EDT/EDP, shampoo, detergent, softener, aerosol, candle wax).

- Compliance check: Validate IFRA limits, potential allergens, and regional requirements; adjust ratios or swap molecules.

- Stability & compatibility: Heat/light/pH, surfactant compatibility, color drift, packaging absorption, fabric deposition.

- Pilot → Scale-up: Lock formula, define QC specs, issue COA templates, and document change-control.

- Post-launch care: Monitor sensory regression, raw material shifts, cost, sustainability opportunities.

FY’s role: We support steps 3–8 with GC-MS diagnostics, IFRA assessments, microencapsulation, and pilot-to-scale coordination—often within two weeks for standard briefs.

Palette & Materials: Naturals, Synthetics, and Hybrids

Naturals (essential oils, absolutes, resins, concretes) offer authenticity and complexity but can vary by harvest, geography, and season.

Synthetics provide consistency, precision, and access to accords not found in nature. Most successful formulas use hybrid palettes, with naturals for identity and synthetics for structure and longevity.

Macro Comparison

| Dimension | Naturals | Synthetics | Hybrid Guidance |

|---|---|---|---|

| Supply & cost | Seasonal/variable | Predictable | Use naturals for signature; synthetics for stability |

| Stability | Heat/light/oxidation sensitive | Engineered robustness | Add antioxidants/encapsulation; manage headspace |

| Sensory | Rich, nuanced | Tunable & precise | Overlay natural top markers on synthetic base |

| Compliance | Allergen risks | Easier to target limits | Run IFRA early; design to window |

| Storytelling | Origin narrative | Tech/performance story | Blend both for clean-label + performance |

FY tip: In functional products (detergent, shampoo, softener), start from a synthetic backbone for process tolerance, then add small, high-impact naturals to secure a recognizable signature.

Tools & Methods: How Perfumers Design and Verify

- GC-MS: Generates a volatile “fingerprint,” helps replicate references, diagnose off-notes, and track batch consistency.

- GC-O & AEDA: Nose-on-the-chromatograph to identify odor-active components and rank their impact.

- Stability protocols: 40–50 °C accelerated aging, photostability, pH cycling; fabric deposition and rinse-off tests where relevant.

- Delivery systems:

- Microencapsulation for fabric care and body care (pressure/heat/rubbing release).

- Immobilization/solid carriers for bars, powders, and unstable matrices.

- Base-specific adjustments: Solvent swaps (ethanol/DPG/IPM), co-solvents, antioxidants, chelators, and pH buffers.

FY capability: GC-MS reports on request, IFRA dossiers, and multiple release-profile options (e.g., capsules with different rupture thresholds).

Fine Fragrance vs Functional Fragrance

| Aspect | Fine Fragrance (EDT/EDP/Parfum) | Functional (Home/Personal/Oral/Fabric) |

|---|---|---|

| Primary goal | Signature & emotion | Performance in complex bases |

| Constraints | Artistic identity, sillage | Heat/pH/surfactants/oxidants, cost-in-use |

| Palette | Rich naturals, long bases | Low-odor backbones, encapsulation |

| KPIs | Trail, longevity, uniqueness | Stability, deposition, compliance, price |

| Testing | Blotter/skin, longevity | Base-side tests, stress & compatibility |

Compliance 101: IFRA, Allergens, and Safety

- IFRA Categories set maximum use levels per product type (e.g., cat 4 fine fragrance vs cat 9 wash-off).

- Allergen disclosure (e.g., EU) and regional rules can affect labeling and allowable levels.

- Safety margins: Perfumers design to stay comfortably within limits across supply variation and batch tolerance.

- Documentation: IFRA conformity certificates, allergen lists, SDS, COAs, and change-control procedures.

FY compliance support: IFRA-aligned usage windows, allergen quantification, and country-specific guidance to accelerate regulatory sign-off.

Case Examples (Condensed)

1) Fresh Citrus Fabric Softener (Cat 9)

Brief: Clean, bright citrus that survives wash/rinse/dry and leaves a soft trail on textiles.

Approach:

- Synthetic backbone (aldehydes: citral, decanal) for brightness + stability.

- Small % of terpeneless citrus oil for natural signature without clouding.

- Microcapsules tuned to rupture on rubbing/wearing; antioxidant system to prevent yellowing.

Outcome: Higher post-laundry perception and longer fabric trail with good cost-in-use.

2) Minty Oral-Care Profile (Cat 6)

Brief: Instant cooling at brushing, sustained freshness afterward, low bitterness.

Approach:

- Peppermint oil for “natural mint” identity.

- WS-series coolants (e.g., WS-3/WS-23) to create burst + long-lasting cooling.

- Bitter blockers and compatible carriers for surfactant matrix.

Outcome: Layered cooling curve, reduced medicinal off-notes, strong consumer acceptance.

FY add-on: We provide two to three mod options for each case with GC-MS support and IFRA windows, then iterate to target KPI.

KPIs and Evaluation Metrics

- Sensory: intensity over time (top/heart/base), sillage/trail, bloom, balance.

- Technical: stability (heat/light/pH), base compatibility, color drift, packaging sorption.

- Regulatory: IFRA compliance margin, allergen totals, regional labeling readiness.

- Commercial: cost-in-use, raw material lead times, sustainability (bio-based %, upcycled content).

- Scale: batch reproducibility, QC spec robustness, change-control impact.

Common Pitfalls—and How Perfumers Avoid Them

- Ignoring the real base: Always test in the product matrix early; ethanol/blotter results can mislead.

- Underestimating oxidation: Add antioxidant systems; manage headspace and light exposure in storage.

- Over-naturalizing functional products: Beautiful, but unstable—use naturals surgically with a synthetic chassis.

- Late compliance checks: Run IFRA windows at mod stage to prevent costly rework.

- Poor documentation: Lock specs and traceability to protect performance over time.

Working with FY: From Idea to Scalable Scent

- IFRA-compliant fragrance bases tailored to product categories.

- GC-MS diagnostics for benchmarking, reverse-engineering, and troubleshooting.

- Microencapsulation/immobilization libraries with multiple release triggers.

- ISO/Halal certifications, full COA/SDS/Allergen packs.

- Fast iteration & free sampling: Typically 3 sample options and a recommended usage window; pilot-to-scale support.

Get started: Share your base (pH, solvents, surfactants), IFRA category, target notes, and budget. We’ll return two to three mods and a test plan—usually within 5–10 business days.

Frequently Asked Questions

Q1: Do perfumers only use natural ingredients?

No. Most modern formulas are hybrids—naturals for signature and synthetics for stability, consistency, and cost-in-use.

Q2: What makes a scent last longer?

Fixatives, careful base-note design (woods/amber/musk), and delivery tech (microcapsules, immobilization) aligned to the product matrix.

Q3: Why doesn’t a great blotter test work in my shampoo?

Surfactants, pH, and water activity change volatility and deposition. Always run base-side tests.

Q4: How does IFRA affect formulation?

It sets maximum use levels by category. Perfumers design to stay within these while meeting sensory goals.

Q5: Can FY help with compliance and documentation?

Yes—IFRA statements, allergen reports, COA/SDS, and guidance on regional labels.