- Date: 2 September 2025

The Science Behind Food Flavoring: How It Affects Taste and Nutrition

- 12 min read

- 0 comment

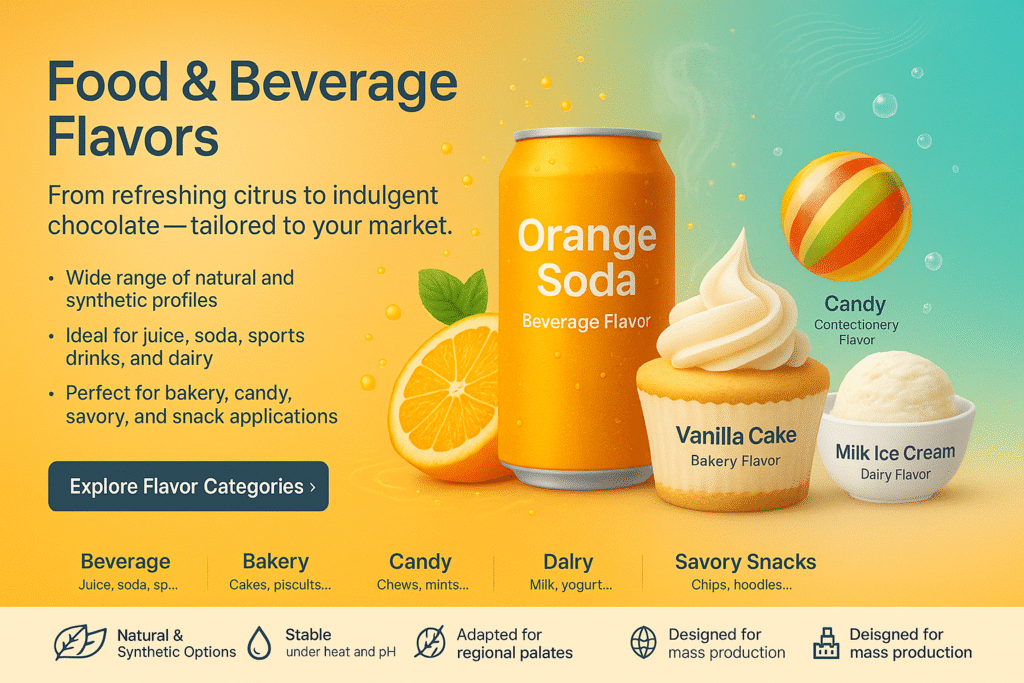

Tailored solutions for food, beverage, personal care, and home care industries.

At F&Y, we specialize in creating and delivering high-quality, customized cosmetic fragrances, everyday household fragrances (detergents, laundry detergents, shampoos), and food and beverage fragrances (beverages, wines) solutions to meet the unique needs of global manufacturers and brands. Whether you are looking to enhance an existing product or develop a new one, our team of experts will provide you with innovative, market-ready fragrance configurations to elevate your product and set you apart from the competition. Tell us about your product challenges and let us transform them into sensory successes.

Our flavors are used in juices, dairy products, baked goods, candies, and snacks. Our fragrances are suitable for detergents, shampoos, soaps, and home care products.

Yes, we offer free samples for most of our flavors and fragrances. Please fill in the contact form to request yours.

Absolutely. All of our fragrance formulas comply with IFRA guidelines and can be customized for sensitive skin or reduced allergens.

Yes. We work with both global brands and smaller manufacturers to offer full OEM and ODM solutions tailored to local markets.

Yes, our R&D team provides fragrance or flavor matching services if you send us a reference sample.