The Science of Flavor Chemistry: What You Need to Know

The Science of Flavor Chemistry: What You Need to Know

(with FY’s practical experience embedded)

One-sentence quick read: Flavor chemistry studies the chemical basis of aroma + taste + mouthfeel, and applies natural and/or synthetic flavor molecules to meet targeted product goals—striking the best balance among stability, reproducibility, cost, and compliance. As a flavor and home-care fragrance manufacturer, FY provides IFRA/ISO/Halal compliance, GC-MS analysis, microencapsulation/controlled release, and free samples & custom development.

1) What Is Flavor Chemistry?

Flavor chemistry focuses on three components:

- Aroma: volatile compounds (aldehydes, ketones, alcohols, esters, lactones, terpenes, etc.) that define “what it smells like.”

- Taste: sweet, sour, bitter, salty, umami—and trigeminal sensations such as pungency/cooling/tingling.

- Mouthfeel & aftertaste: texture, astringency, fattiness, and finish.

Beyond explaining “why strawberry tastes like strawberry,” flavor chemistry solves industrial problems: heat/acid resistance, off-note masking, release curves, batch consistency, and regulatory compliance—so beverages, bakery, confectionery, and oral-care products deliver a stable experience globally.

FY tip: We front-load target experience → process window → regulatory boundary at the project kickoff to avoid late rework.

2) How Is Flavor Chemistry Applied? (From Lab to Shelf)

Typical flow: target definition → molecule library screening → build the accord (flavor backbone) → base-matrix compatibility → stabilization (antioxidants/encapsulation/carriers) → sensory & physico-chemical tests → pilot → scale-up.

Common scenarios & strategies:

| Application | Key Conditions | Main Challenges | Go-to Strategies |

|---|---|---|---|

| Acidic beverages | pH 2.5–4.0, pasteurization/hot-fill | Oxidation, clouding, separation | Terpeneless citrus, antioxidant system, emulsification or encapsulation |

| Bakery | 160–200 °C | Thermal degradation, Maillard interactions | Heat-stable molecules, late-stage spraying, immobilization |

| Confectionery/Gum | High sugar/polymer bases | Too-fast or too-weak release | Bi-phase/multi-stage release, cooling agents |

| Oral care | Surfactant systems, near-neutral pH | Bitterness/astringency/medicinal notes, retention | Maskers, WS-series coolants, fixation |

| Dairy/Coffee | Fat/protein interactions | Adsorption & flavor muting | Dual (oil-/water-soluble) systems, emulsification & carrier design |

FY in practice: For long-lasting scent in fabric-care/oral-care, we offer microcapsules with different rupture thresholds and immobilized systems tailored to triggers like rubbing, heat, or shear.

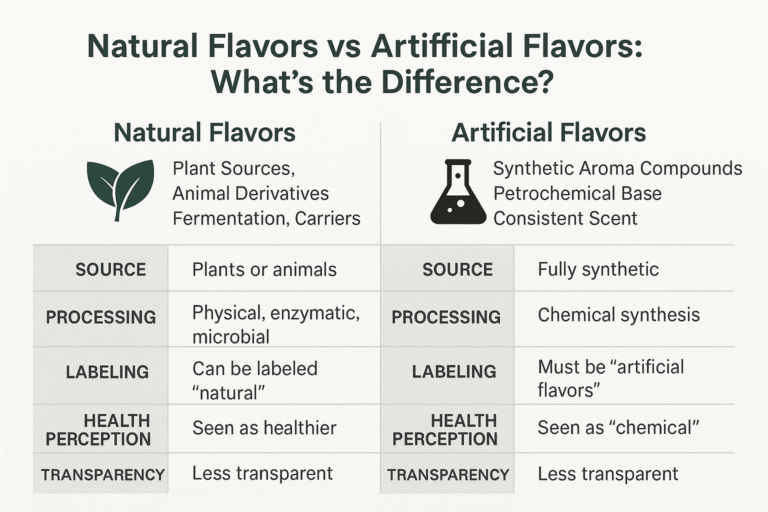

3) Natural vs. Artificial Flavors (Macro Comparison)

Definitions

- Natural flavors: obtained from plant/animal/microbial sources via physical methods, enzymes, or fermentation.

- Artificial flavors: synthetic or “nature-identical” single molecules and designed accords.

Selection principle: Increase natural proportion for origin storytelling/clean label; rely on artificial or natural + artificial hybrids for consistency, process robustness, and cost.

| Dimension | Natural Flavors | Artificial Flavors | Hybrid Strategy (Recommended) |

|---|---|---|---|

| Supply & Cost | Seasonal/region-dependent | Stable, controllable | Natural for signature top note; artificial for base |

| Stability | Prone to oxidation/heat/light | High process tolerance | Natural + antioxidants/encapsulation |

| Sensory | Authentic complexity | Tunable curve | “Authenticity + longevity” together |

| Compliance | May contain allergens | Can be engineered to limits | Run IFRA/FEMA assessment early |

FY capability: Within IFRA/EU/FDA bounds we propose usage windows and deliver COAs/allergen lists and compliance statements.

4) Natural Flavors (In-Depth)

- Sources & processes: cold-pressed citrus, distilled mint, supercritical CO₂ vanilla, fermented vanillin, etc.

- Strengths: vivid top notes and origin storytelling.

- Challenges: batch variability, potential allergens (e.g., oxidized limonene), photo/thermal sensitivity.

- Stabilization: deterpenation/fractionation, antioxidants, encapsulation/immobilization, synergy with artificial monomers to reconstruct mid/base.

FY case: For a citrus drink we used terpeneless orange oil + citral/decanal to keep brightness, plus an antioxidant system to reduce discoloration and off-notes.

5) Artificial Flavors (In-Depth)

- Types: single molecules (vanillin, ethyl maltol, citral, linalool, lactones, etc.) and complex accords.

- Strengths: reproducible, process-resistant, cost-stable.

- Strategy: build a performance base with artificial molecules, then add a measured amount of natural oil/extract as a top-note marker for realism.

FY experience: In mint systems for oral care we combine peppermint oil + WS-3/WS-23/menthyl lactate to achieve a “burst + long-lasting” cooling pathway.

6) Common Flavoring Chemicals (Categories & Uses)

- Key aroma builders:

- Vanillin/Ethyl vanillin (vanilla/creamy), citral/nonanal/decanal (citrus brightness), linalool/linalyl acetate (floral), γ-nonalactone/δ-decalactone (milky/coconut).

- Taste & enhancers:

- MSG, 5′-IMP/5′-GMP (umami synergy), ethyl maltol (sweet/caramelized), citric/malic acid (acid backbone).

- Cooling/Warming:

- WS-series, menthyl lactate (layered cooling), vanillyl derivatives/gingerols (warmth).

- Masking/Blocking:

- Bitterness blockers, metal chelators, slow-release matrices for acids/sweeteners.

- Auxiliary systems:

- Carriers (propylene glycol, triacetin), antioxidants (ascorbic acid, TBHQ), emulsifiers, encapsulation wall materials (modified starch/gum arabic).

FY reminder: All dosages must meet target-market regulations (FEMA GRAS/EU/21 CFR/GB). Validate sensory thresholds in the actual base.

7) How to Use Flavor Extracts (Practical Guide)

1) Selection & verification

- Check COA/solvent & carrier/allergens/photo-thermal stability.

- Run accelerated aging (40–50 °C, light) and base-side tests (pH, surfactants, fat content).

2) Dosing & addition point

- Choose cold-end or late-stage addition for volatile/heat-sensitive notes.

- Pre-mix oil-/water-soluble systems separately; control shear and temperature to prevent stripping.

3) Quality & compliance

- Benchmark against FEMA GRAS, EU 1334/2008, 21 CFR, etc.

- Label distinctions: “natural/nature-identical/artificial,” plus allergen declarations.

4) Optimization & synergy

- Use artificial monomers to reinforce mid/base or process tolerance.

- Apply encapsulation/immobilization to boost longevity and process stability.

FY services: GC-MS profiles and scent-curve assessments, plus 2–3 actionable formula windows and samples tailored to your base (free sampling supported).

8) Compliance & Quality Control (E-E-A-T Strengthening)

- Frameworks: FEMA GRAS list, EU 1334/2008, US 21 CFR, China GB; extra care for oral-care/children’s products (limits and maskers).

- Documentation & traceability: batch consistency, retain samples, stability & allergen reports, Halal/vegan conformance.

- Use principle: only in necessary categories, and use the minimum needed (GMP) once the effect is met.

FY credentials: IFRA compliance, ISO QMS, Halal certification; full-chain documentation and audit support.

9) Forward-Looking Trends (12–24 Months)

- Bio-synthesized/fermentation-derived aroma molecules: lower regional volatility and carbon footprint, higher consistency.

- Clean label & upcycling: fractions from fruit-juice/wood byproducts expand the natural pool.

- AI × sensory databases: multi-objective optimization (cost, compliance, preference, longevity).

- Precision release & new wall materials: multi-stage delivery tailored to textile care and oral-care use.

- Cross-category flavor language: parameterized migration of, say, “citrus” across beverage/confectionery/oral-care.

FY update: We’re piloting upcycled citrus and multi-threshold microcapsules; co-development partners are welcome.

10) Conclusion

Start with the base and process window to back-solve your route: raise natural proportion when you need “authentic storytelling,” and rely on an artificial backbone with stabilization when scaling under tough conditions—then accent with natural top notes for realism. Keep compliance and quality control end-to-end.

FAQ

- How does flavor chemistry relate to food additives?

Flavor chemistry studies flavor molecules and their use; flavors are a class of food additives governed by dosage and labeling rules. - Which is safer—natural or artificial flavors?

Safety depends on dose and compliance, not origin; both must meet regulations. - Why does the same flavor behave differently across categories?

Base pH, fat, surfactants, and temperature alter release and stability. - How do I improve citrus flavor stability in acids/oxidation?

Use terpeneless oils, antioxidants, and emulsification/encapsulation; reinforce with citral/decanal if needed. - How to achieve “burst + long-lasting” cooling in oral care?

Combine peppermint oil with WS-series coolants for multi-stage release. - What’s the difference between encapsulation and microcapsules?

Encapsulation is broad protection; microcapsules emphasize triggered release (pressure/heat/friction). - How do “natural,” “nature-identical,” and “artificial” differ on labels?

They reflect source and process; follow your target market’s definitions. - How do I evaluate supplier consistency?

Review COAs, allergen lists, stability reports, batch variation, traceability—and request GC-MS data. - Can artificial flavors fit clean-label strategies?

Yes—use minimal, performance-oriented doses within natural-forward + artificial backbone hybrids. - Are fermentation-derived molecules more sustainable?

Often more consistent with a lower footprint, but still require sensory and regulatory validation.

About FY

FY specializes in food and home-care flavors/fragrances, offering IFRA/ISO/Halal compliance, GC-MS testing, microencapsulation/immobilized controlled release, and custom development. We support free sampling and rapid pilot-to-scale transitions. Share your base parameters/target flavor/regulatory region, and we’ll return formula windows and testing advice within 48 hours.